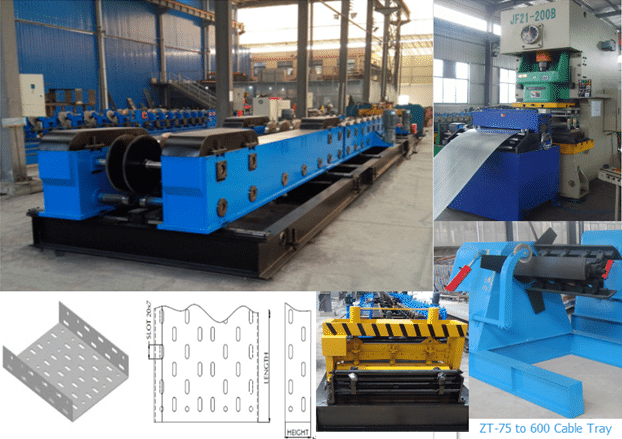

ZT-75 to 600 fully automatic cable tray rolling machine

ZT-75 to 600 fully automatic cable tray rolling machine produced cable trays that are used in different kind of factories and buildings.

We offering you to Cable Tray Machine that comprise of efficient Punching Press, Hydraulic Press, Electric Control penel and many other Equipment, which make it an ideal option for many. The Cable Tray Roll Forming Machine can Manufacring a both superiority and quantity cable trays in less time.

The ZT-75 to 600 fully automatic cable tray rolling machine is composed by the following elements: hydraulic decoiler, leveling system, punching machine,coil feeder, mian rolling forming machine and receiving table.

What is the Application of cable tray machine?

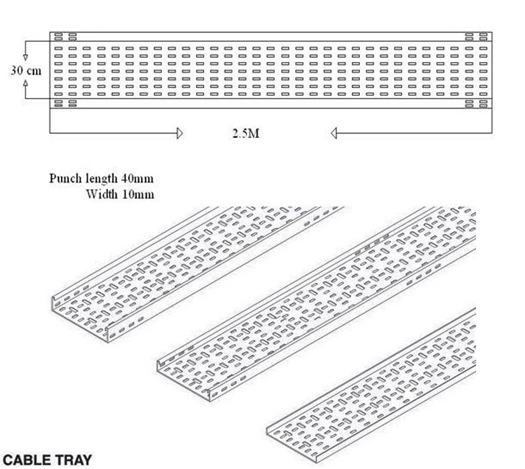

Galvanized Steel cable tray machine is a kind of equipment for making cable tray by various material. In the electrical wiring of buildings, a cable tray system is used to support insulated electric cables used for power distribution and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe. For zhongtuo cable tray Roll Forming Machine is a kind of machine for making cable tray by roll forming principle.

Zhongtuo cable tray machine is composed by the following elements:

De-coiler

Parameter: width of material: 225-1020mm thickness: 1-2mm;

Inner diameter of coil: 508mm;inner expansion range: 480-520 mm;

The maximal of Diameter: 1500mm; The Maximal of loading: ≤5T

Motor power: 5.5kw frequency change control

Press material type: pneumatic press material

Feeding speed: 0-15m/min, adjustable

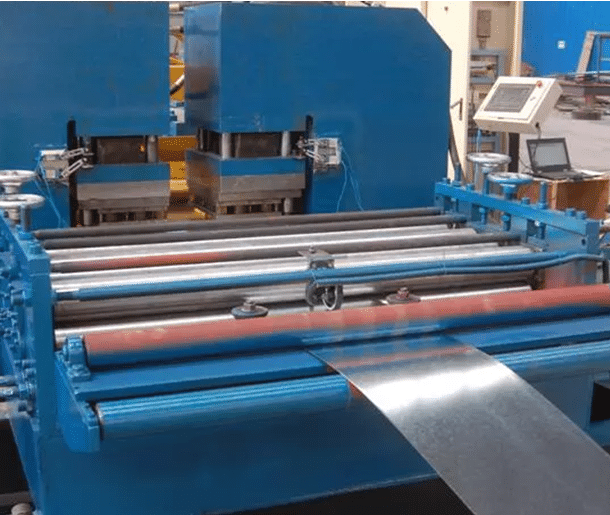

Leveling machine of fully automatic cable tray machine

A: working roller: nine rollers type leveling machine

B: Feature of structure: after the quenching and tempering, chrome-plating processing, the rigidity, surface roughness of the roller etc. are all enhance greatly; It is composed by the clamping roller and the leveling roller, the clamping roller may the independent control, the leveler has one pair of horizontal guide roller and two pairs of vertical guider roller and easy to adjust by hand wheel. Between the leveler and the feeding device, there is optical sensor, sends out the feedback signal to the control system, the control system sends out the instruction to the frequency conversion motor to change speed, Achieves the uninterrupted level goal.

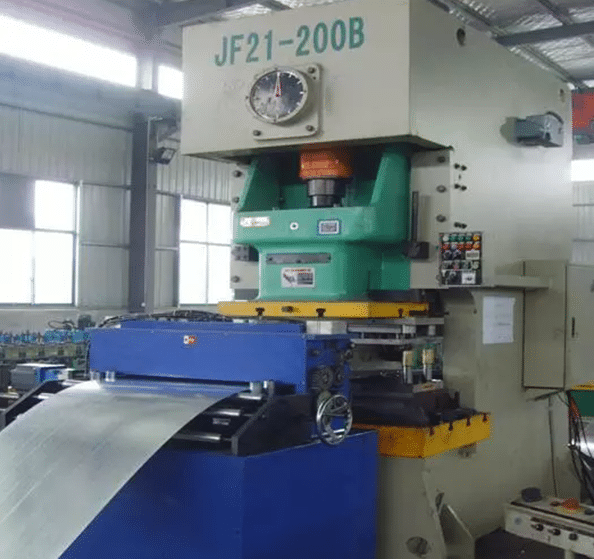

Punching press of Model of punching press: JF21-120B

Roll forming part

Forming station: 14sets

Forming variety: bridge frame

The diameter of the roller axis: 85mm

Features of main cable tray rolling forming machine:

Thickness:1.0-2.0 mm;

Forming speed:3-6 m/min.

Main shafts of molds:φ60 mm,40Cr hardening and tempering

Lateral plate:27 mm steel plates

Body of machine:350H welded steel plate

Motor power:Main transmission: 4KW K series of spin chute gear motor 2

Sets, 5.5 KW K series of spin chute gear motor 2 sets.

Motor power of side-to-side adjustment:1.5 kw motor 1 set, 1.1 kw motor 1 set.

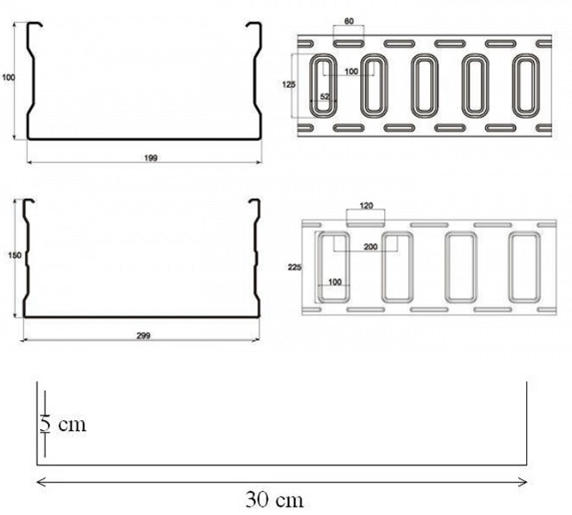

Adjusting range of side-to-side:100mm-600mm.

Adjusting range for height of lateral plate: 50-200mm.

at the same time, can produce cover board (with width of 100~600 mm)

(Width and depth are adjustable. Error on working length: ±1.5 mm.

Straightness error 2‰)

FAQ:

1.Does one 75 to 600 fully automatic cable tray rolling machine can only produce one style product?

Not exactly. Our machines can produce more kinds of by change their rollers.

2. Do you have after sales support?

Yes, we are happy to give advice and we also send skilled technicians to your place to support the technical guidance. We will let your machines running that in order to keep your business running.

3. What can you do if the machine broken?

Our machine's warranty period is 12months. And if the broken parts can't be repaired, we will send the new one to replace the broken parts. And the only thing you need to do is paying the transport costs.

If beyond the warranty period, we can through the negotiation to solve the problems, and we will supply the technical support for the whole life of the machine.

Looking for ideal 75 to 600 fully automatic cable tray rolling machine manufacturer & supplier ? We have a wide selection at great prices to help you get the target product. If you have any question, please contact us.

Looking for ideal 75 to 60 Automatic Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Cable Tray Rolling are quality guaranteed. We are China Origin Factory of Popular Production Line. If you have any question, please feel free to contact us.

Product Categories : Cable Tray Roll Forming Machine

Mr. Cary xu

Mr. Cary xu